Railroad Solutions

Through cutting-edge engineering, ENSCO designs, builds, operates, and delivers world-class track-inspection vehicles and systems that monitor comprehensive performance indicators reflecting track quality and safety.

TRACK INSPECTION SYSTEMS

- URFS: Ultrasonic Rail Flaw Detection System

- TGMS: Track Geometry Measurement System

- RSIS: Rail Surface Imaging System

- V/TI: Vehicle/Track Interaction Monitor

- RQMS: Ride Quality Measurement System

- RPMS: Rail Profile Measurement System

- RCIS: Rail Components Imaging System

- RCMS: Rail Corrugation Measurement System

A world leader in railroad inspection, offering integrated solutions with intelligent technology that improve the safety, efficiency, and reliability of transportation. Develops turnkey platforms enabling data-driven decisions and failure prevention.

Precise Location

Advanced technology automatically identifies the vehicle’s exact position on the track.

Autonomous Inspection

Automated systems reduce risks, optimize costs, and increase inspection frequency.

Global Technology

Turnkey platforms enable data-based decisions and fault prevention.

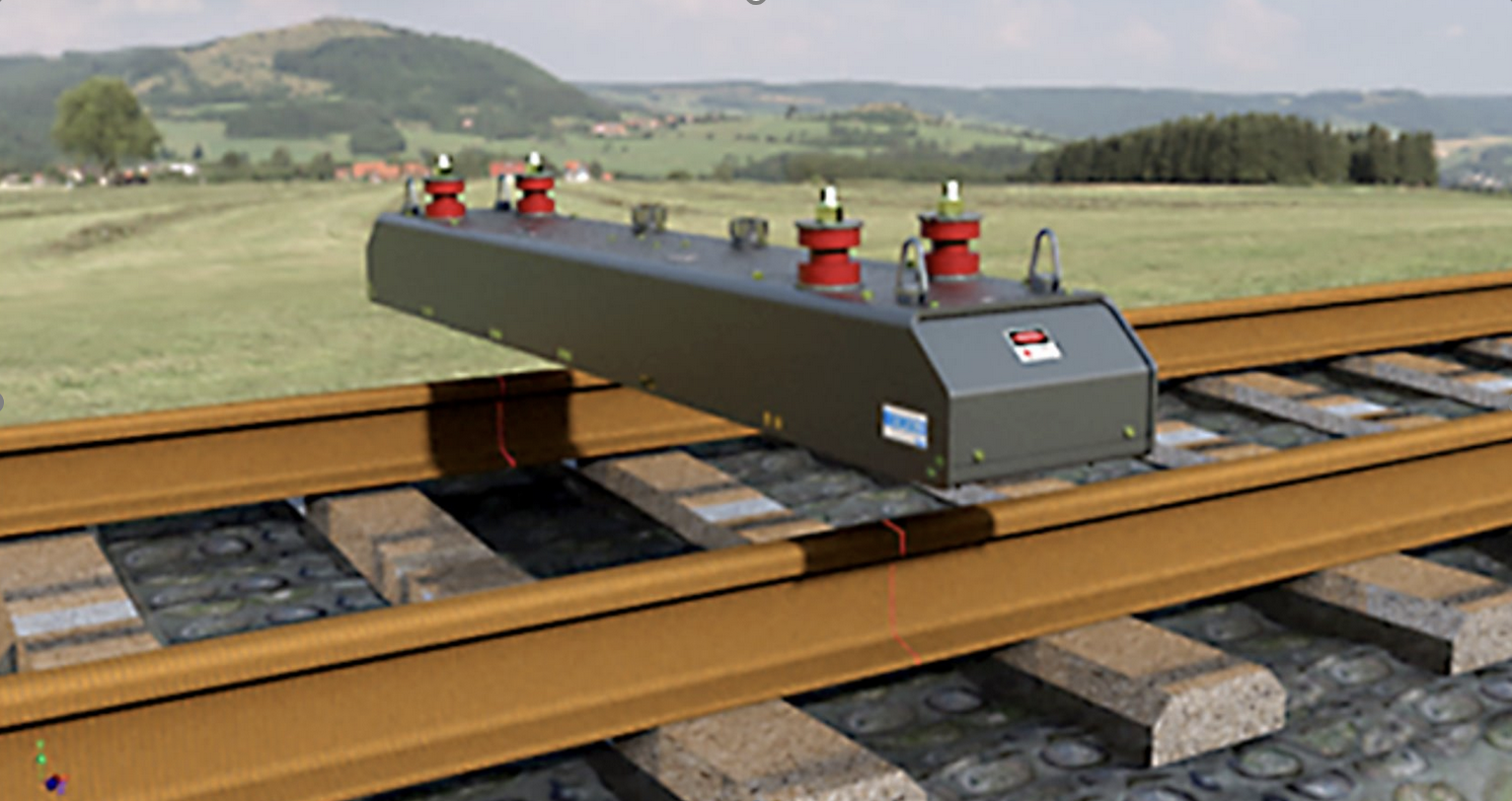

URFS

Ultrasonic Rail Flaw Detection

Prevents rail and weld breaks using complementary technologies and skills—helping railroads meet regulations, prevent derailments, and keep lines operating safely and efficiently.

TGMS

Track Geometry Measurement

Ensures track geometry remains within prescribed limits for safe operations.

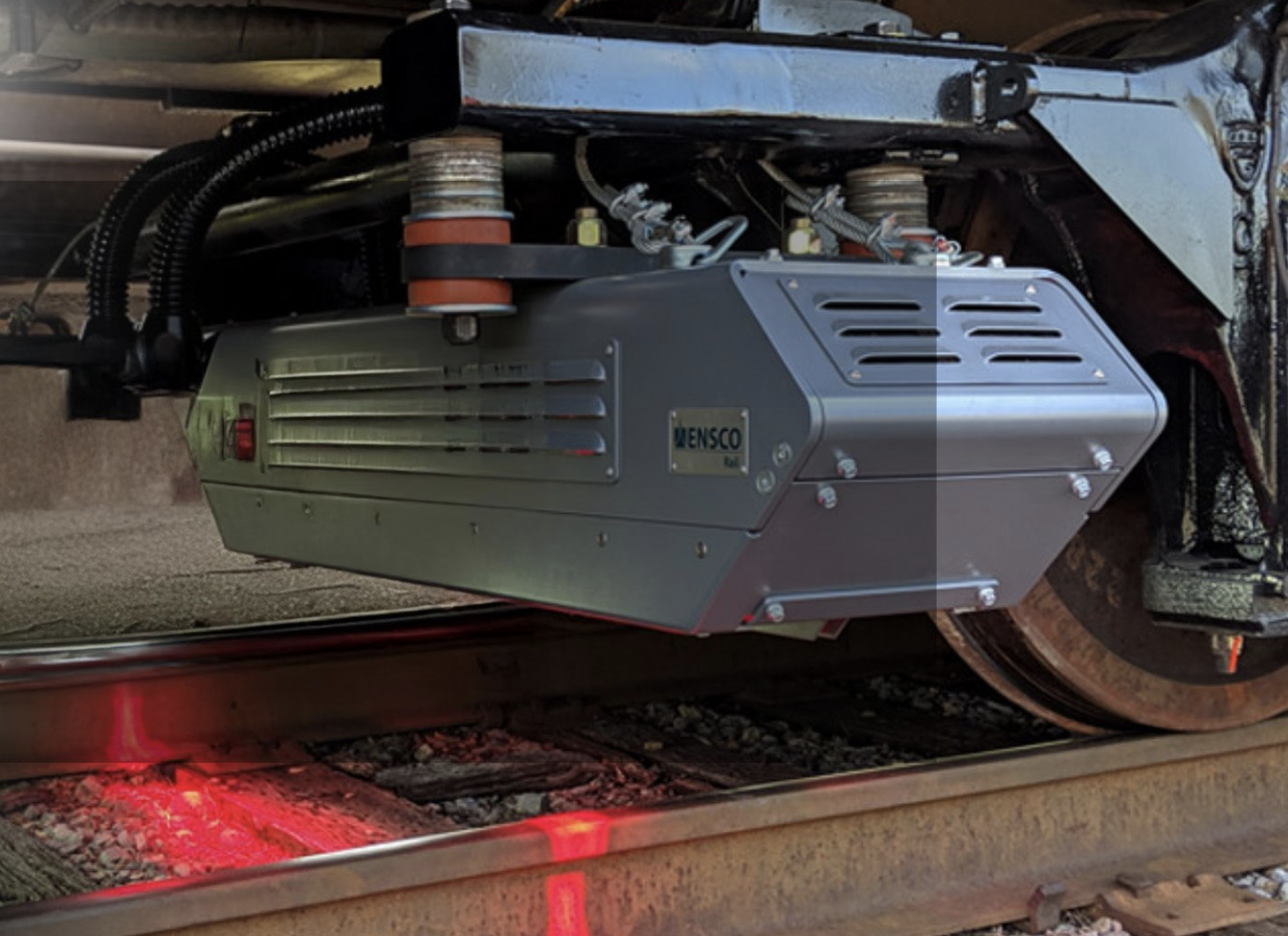

RSIS

Rail Surface Imaging

High-speed cameras capture detailed, non-contact rail-surface images; ENSCO’s patented algorithms assess RCF and surface damage, visualized in band charts synchronized with images and other inspection data.

RQMS

Ride Quality Measurement

Provides complementary data on track condition and geometry. Body, suspension, and wheel acceleration can be synchronized with geometry and machine-vision data. Advanced signal-processing pinpoints flats, battered joints, motor burns, crushed railheads, and more.

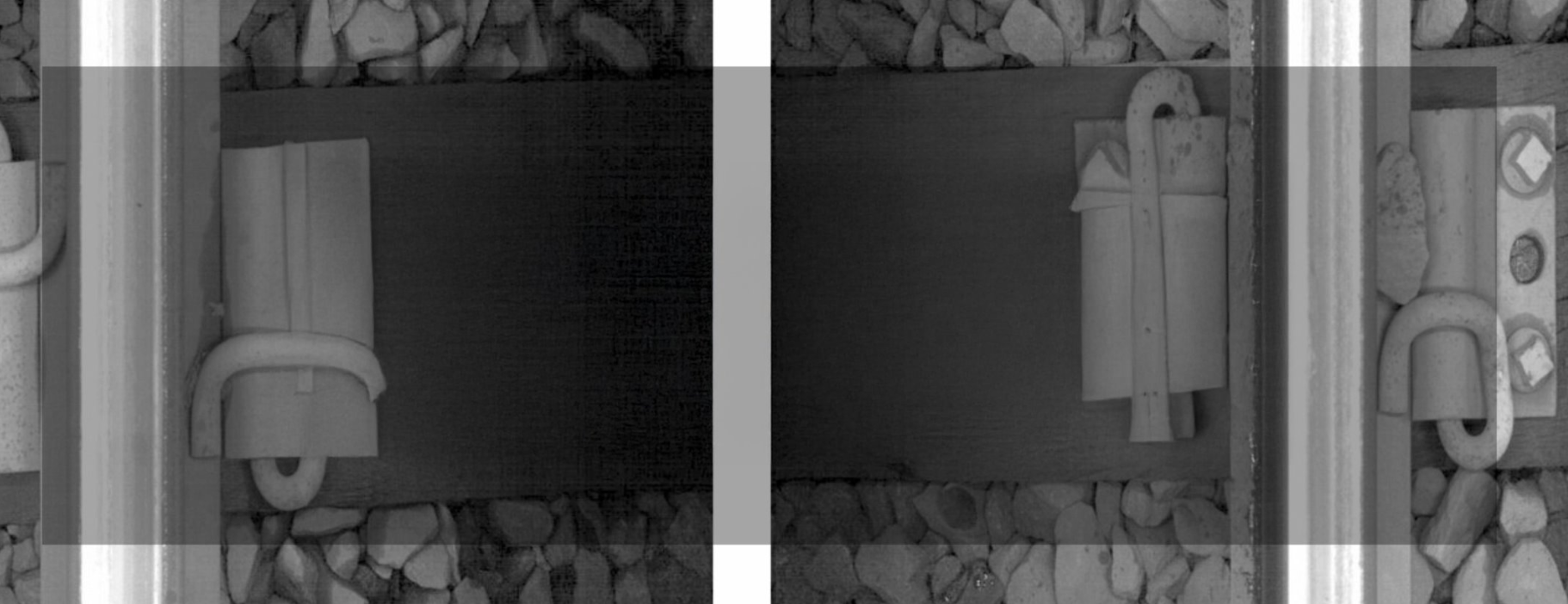

RCIS

Rail Components Imaging

Combines the best of RSIS and the Tie/Component Imaging System (TCIS) to capture high-resolution images of rail surface, fastenings, and sleepers near the fastenings.

RCMS

Rail Corrugation Measurement

High-precision system measuring corrugation across critical wavelength bands for comprehensive assessment—key to locating areas requiring rail maintenance to correct corrugation and restore optimal wheel-rail behavior.

RPMS

Rail Profile Measurement

Rail wear is among the most important metrics for asset management. RPMS is a laser-profiling complement to TGMS that delivers the necessary profile measurements for track maintenance and management.

V/TI (VTI) – Vehicle/Track Interaction Monitor

Includes two axle sensors to measure wheel-rail impacts, a bogie sensor for lateral motion, and two sensors inside the locomotive to measure lateral and vertical cab movements.